Ion Beam Sputtering (IBS) coated laser optics

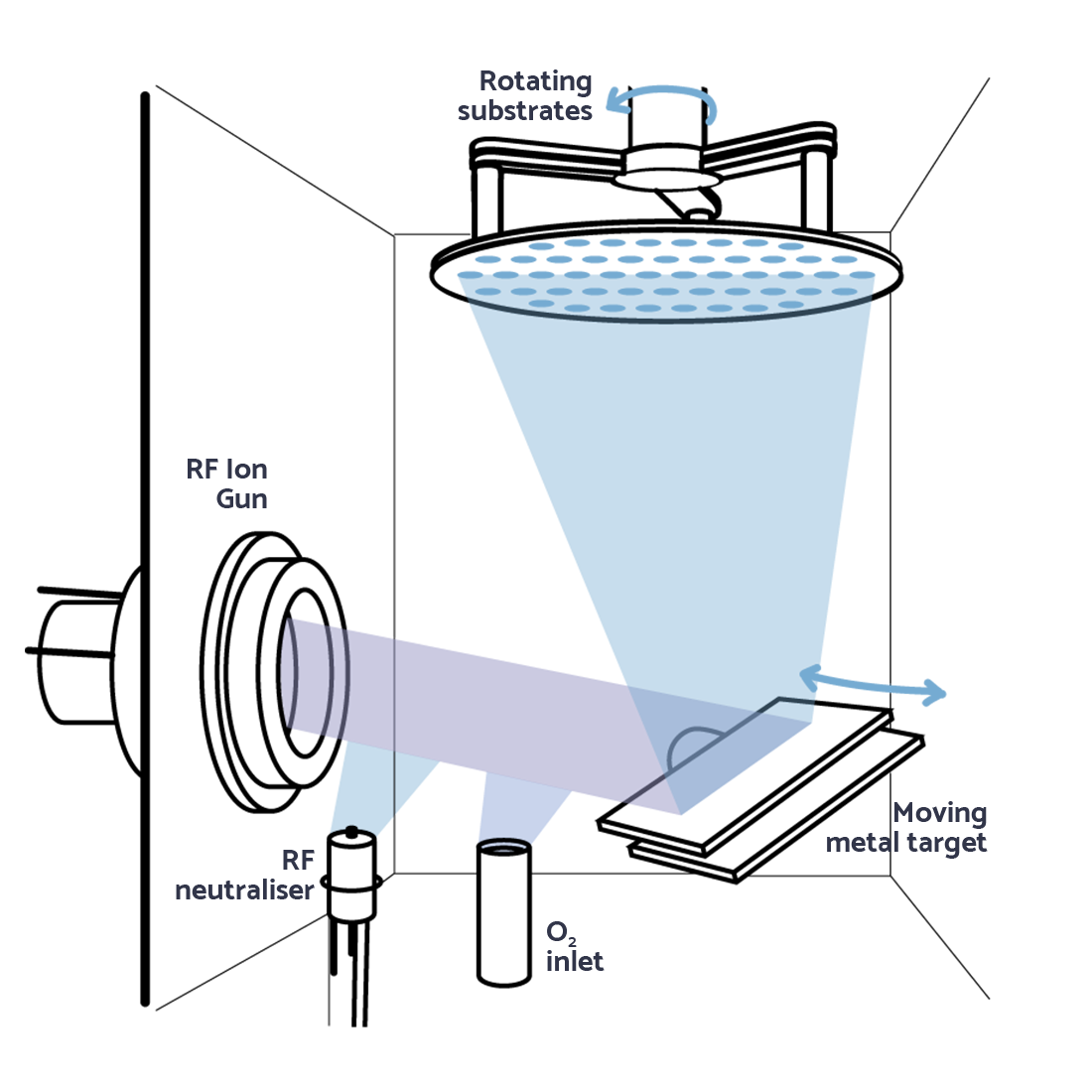

Ion Beam Sputtering (IBS), also known as Ion Beam Deposition (IBD), is a Physical Vapour Deposition (PVD) method where a targeted material is bombarded with a high-energy, precisely directed ion beam, causing molecules to detach and form a thin layer of the material. In short, this technique is fundamental to producing IBS coated laser optics via ion beam sputtering.

Layering materials with carefully controlled thicknesses achieve optical interference coatings. Coatings made using IBS technology consistently meet the highest standards of industry and scientific applications, offering significant advantages for manufacturers of lasers and laser systems. For many, Ion Beam Sputtering (IBS) coated laser optics provide the reliability and performance essential for today’s advanced systems.

Inherently stable sputtering process

- prevent the spreading of the beam due to the repulsion among ions; in particular, this is critical when manufacturing advanced laser optics with IBS coated layers.

- prevent electrical discharges in the chamber by neutralising the overall beam charge. Since the ion gun is isolated as a separate device in the chamber, ion beam energy and ion density are very well-controlled parameters. A very stable ion beam combined with a high vacuum (~1×10-4 mbar during the deposition) and ultra-high purity metal targets (>99.99%) result in a super stable deposition process. It enables a fully automatic deposition and the ability to precisely control refractive indices and thicknesses of each deposited layer. Therefore, Ion Beam Sputtering coated laser optics benefit from these precision control parameters.

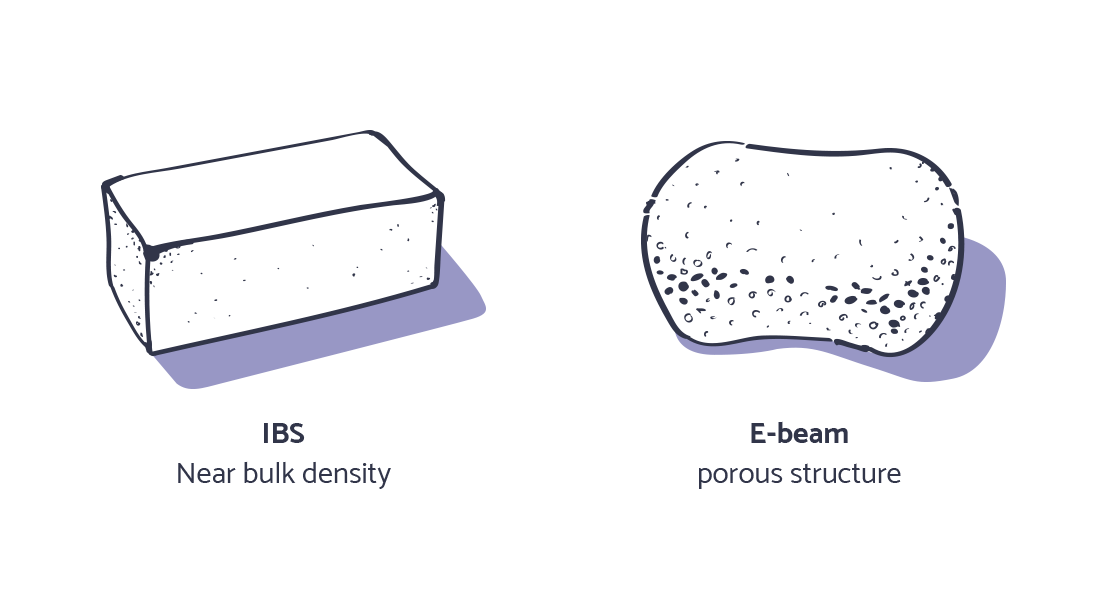

Bulk-like packing density

A sputtered particle (atom or molecule) has times more energy (typically in the range of 10’s eV) than the evaporated one. In such a scenario, particles condensing on the surface are extremely mobile and can easily move across the surface, penetrate and mingle between the already deposited particles. Such film growth does not require additional heating of the substrate and thus creates a very densely packed and completely amorphous structure, a key characteristic for Ion Beam Sputtering (IBS) coated laser optics.

Due to the bulk-like layer’s density, IBS coatings are completely immune to mechanical wear as well as changes in ambient temperature and humidity and ensure smooth operation of your laser in any circumstances. Moreover, our coatings may be used in harsh environments and even in outer space with no change in performance! Importantly, that means Ion Beam Sputtering IBS coated laser optics achieve unmatched stability in challenging conditions.

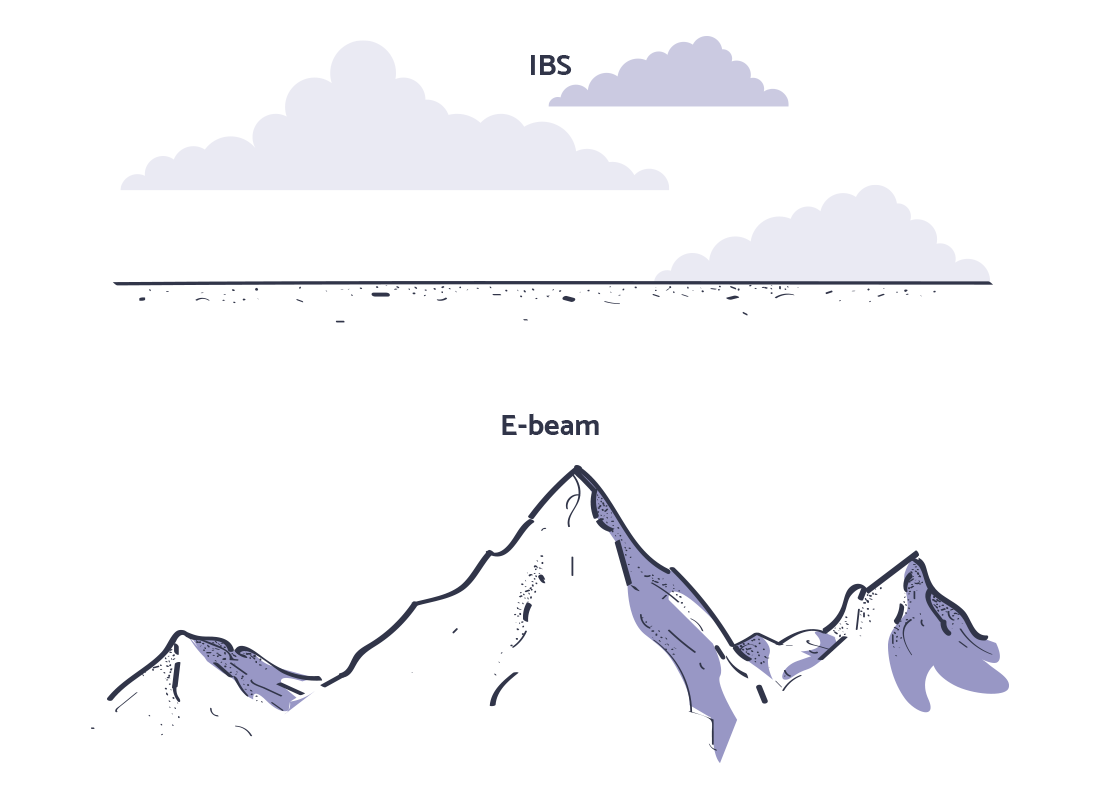

Scattering? What’s that?!

Do you notice any difference in the pictures on the right? The upper one depicts the surface roughness that you will get by using optics from OPTOMAN. Our Ion Beam Sputtering-coated laser optics consistently display minimal scatter due to extreme surface quality.

Due to the near-bulk IBS coating density, the surface roughness of the coated component is mainly determined by the initial substrate roughness. Combine this with the completely amorphous coating layers, and you will end up with almost scatter-free optics.

Forget short-duty cycle issues!

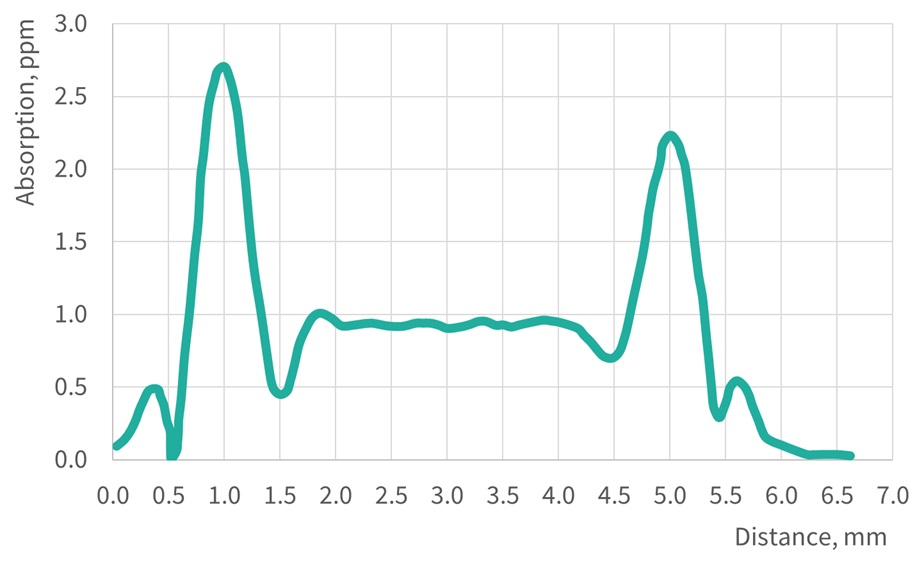

A high and stable vacuum during the process, a large chamber size, extremely pure target materials, near bulk coating density, spatially separated sputtering and material condensation processes which reduce ion implantation to minimum – these are the main reasons why IBS coatings exhibit very low absorption losses. It is well known that such losses are the main cause of thermal effects and a low duty cycle. If you use high repetition rate fs, or a CW system and longevity is your concern, give our coatings a try and you will be surprised! Especially, Ion Beam Sputtering technology ensures your laser optics coated by IBS can operate reliably even in demanding settings.

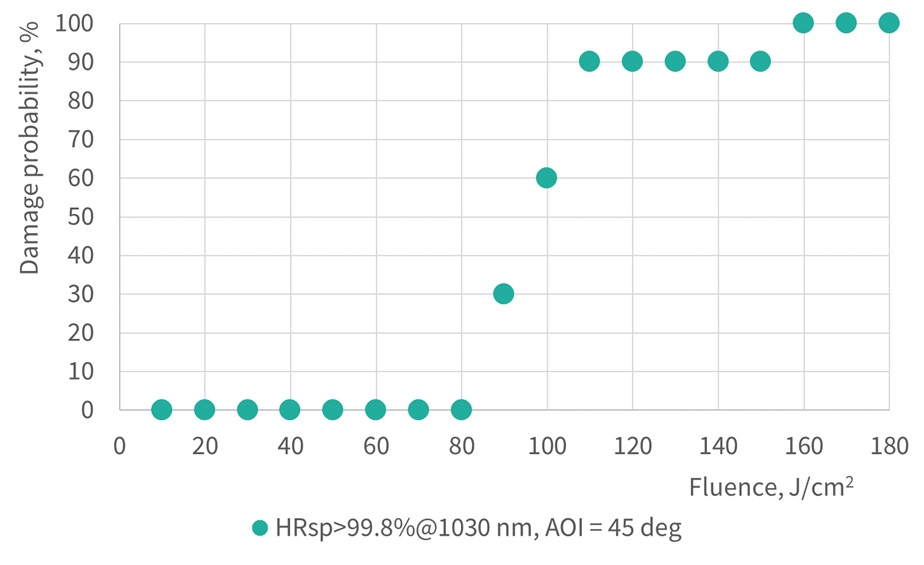

High resistance to laser irradiation

Laser-induced damage of optical components is one of the biggest headaches for high-power laser manufacturers. Coating layers deposited by Ion Beam Sputtering are very dense and pure. By choosing proper deposition parameters and ensuring cleanliness in every step of the manufacturing chain, we are able to produce coatings with very low defect densities. That is the reason why our IBS coatings exhibit excellent resistance to laser irradiation! In fact, when you need optics with Ion Beam Sputtering IBS coatings, laser performance remains uncompromised.

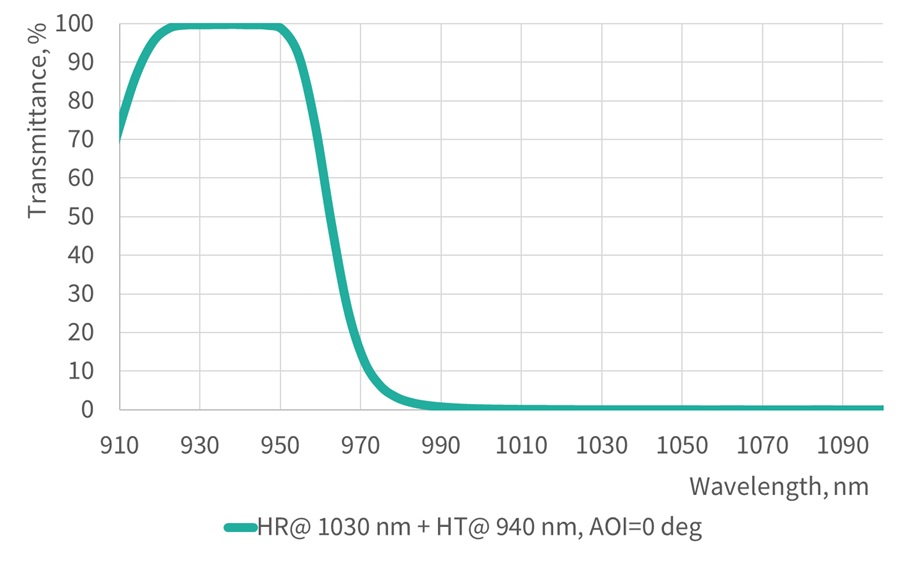

Cutting-edge spectral requirements and repeatability

OPTOMAN is equipped with state-of-the-art broadband optical monitoring. This enables precise layer termination and, together with on-the-fly reverse engineering equipment, allows OPTOMAN to deposit even the most complex non-quarter-wave designs and ensure repeatability between different coating batches. Combination of the advanced optical monitoring and exceptionally low total losses is the reason why we can offer you coatings with cutting-edge spectral requirements! And so, when precise performance is needed, Ion Beam Sputtering (IBS) coated laser optics deliver consistency batch after batch.

Is Ion Beam Sputtering perfect?

Since there are no ideal things in the real world, Ion Beam Sputtering is not an exception. The main drawbacks of this deposition technique are listed below; nonetheless, when it comes to producing high-spec laser optics, the advantages of IBS coated components are clear.

- Lower deposition rates (in comparison with evaporation) of Ion Beam Sputtering IBS coated laser optics can be a limitation for some applications.

- High compressive coating stress (~500 MPa) (however, initial substrate flatness may be maintained by process optimisation or additional manufacturing steps) may impact Ion Beam Sputtering coated laser optics in certain situations.

Having said that, Ion Beam Sputtering is still the best choice for the most demanding laser applications, and by exploiting this deposition technique, OPTOMAN is ready to solve your coating problems for good! So, if you require durable, high-performance optical solutions, consider Ion Beam Sputtering (IBS) coated laser optics as your go-to option.