Optics for Laser Fusion Energy

What can OPTOMAN

do for the fusion energy sector?

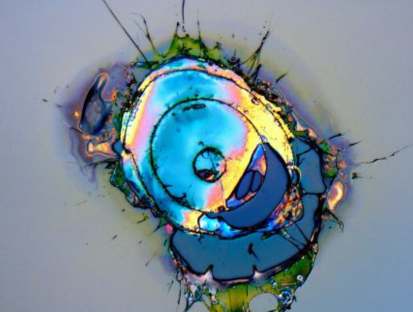

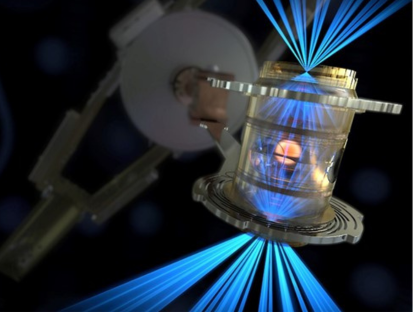

High-power, large-diameter laser optics designed to meet the demands of fusion energy research

FAQ

What sets OPTOMAN apart in the fusion energy sector?

Our commitment to application-optimized, highly customized solutions, combined with customer centric business approach and collaborative development, positions us as a reliable partner in fusion energy research.

Why is Ion-Beam Sputtering (IBS) technology crucial for fusion optics?

IBS provides coatings with bulk-like density, minimal scattering, and high resistance to laser-induced damage, all critical for the demanding environments of fusion applications.

How does OPTOMAN ensure its optics meet the specific needs of fusion energy projects?

We engage deeply with each project, tailoring our solutions to meet specific requirements, whether it’s achieving fundamental research milestones or developing scalable industrial applications.

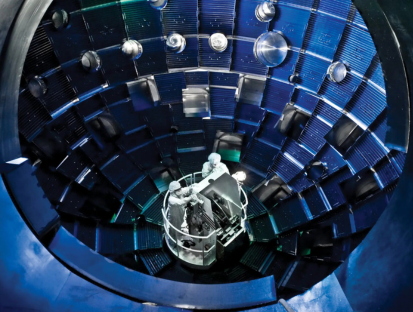

Is it possible to test the optics, and how scalable is the production?

Yes. Based on the customer’s presented business case, OPTOMAN, with its R&D-driven attitude and collaborative approach, can design, develop, and manufacture products for testing purposes and present a plan for serial production. Different-size IBS coating chambers are very handy in this case because small-scale production can be easily transferred to our giant IBS machine – Albert (the atom smasher), where we can coat large optics or 400-500 units of 1“ laser optics in a single coating run, ensuring high uniformity, meaning that all mirrors will work the same making your laser systems highly repeatable and reliable too.

Moreover, our in-stock optics marketplace, OPTOSHOP, features over 400 different laser optics made with love by OPTOMAN. These optics can be provided for testing directly from stock and delivered in 1-3 business days. After successful tests, OPTOMAN can present the most optimal production plan matching your business needs.

We are in the R&D phase; could OPTOMAN help at this stage?

We consider ourselves trailblazers of IBS-based optics manufacturing. We are eager to innovate in the field, so your RnD challenges are our best tasks. The passion for creating something new and our team’s satisfaction from seeing the solutions implemented are huge rewards. We have versatile manufacturing equipment suitable for prototyping and, later on, scalable mass production of thousands of units per day.

Capabilities

Application optimised products

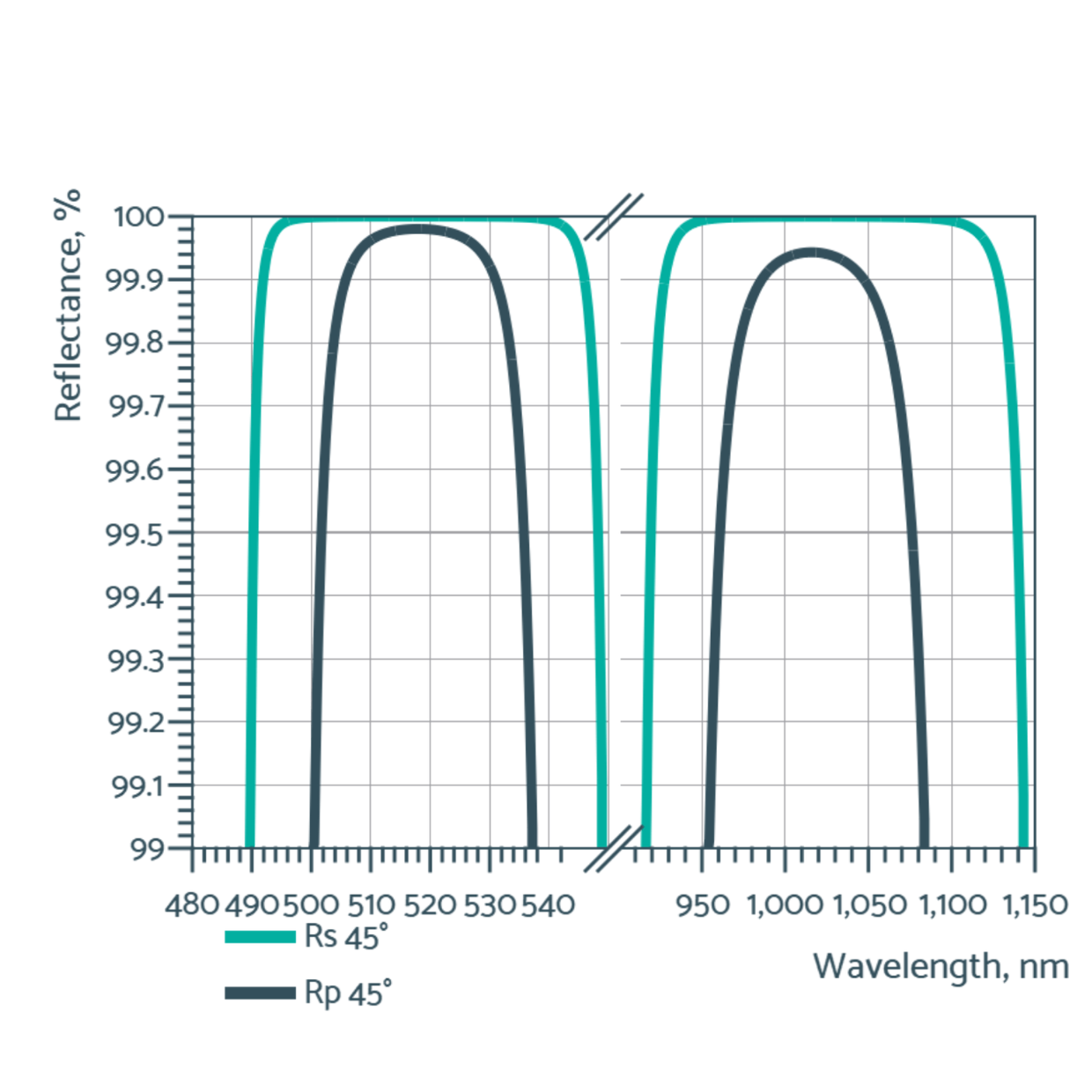

High LIDT Low GDD Multiwavelength mirror for Yb:YAG I and II harmonics.

- Long lifetime

- High LIDT coatings featuring high reflectivity up to 99.99%

- Highly customised and application optimised solutions

Design example

Coating specifications:

HRsp>99.9% @ 1030 nm & HRsp>99.9% @ 515 nm, AOI=45°

|GDD Rs|<10 fs², |GDD Rp|<20 fs² @ 1030 nm & 515 nm, AOI=45°

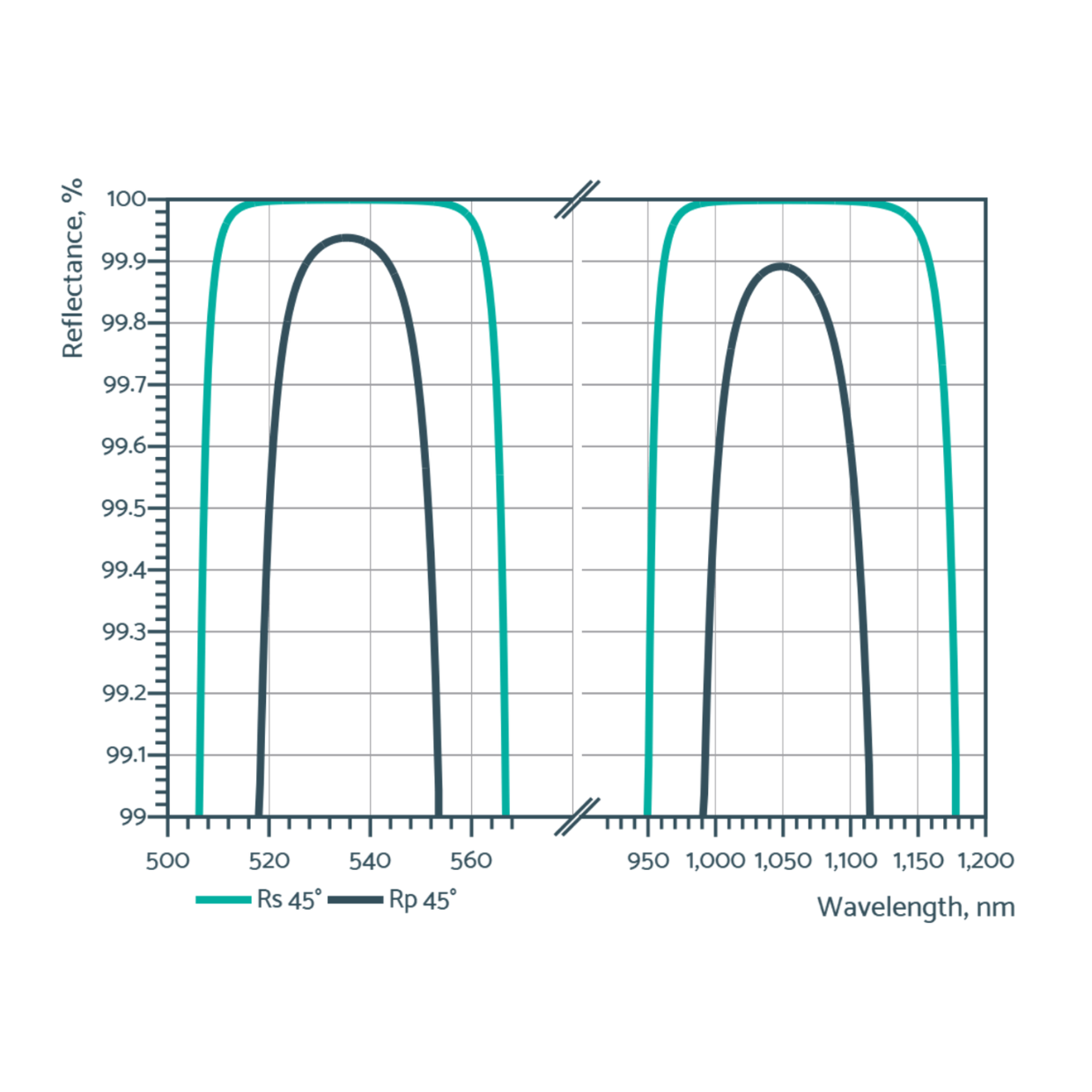

Multiwavelength laser mirror designed for Nd:YAG I and II harmonics.

- High LIDT and low absorption coatings

- High reflectivity at several wavelengths or bandwidths

- Highly customised and application optimised solutions

Design example

Coating specifications:

HRsp > 99.8% @ 1064nm + 532nm, AOI=45°

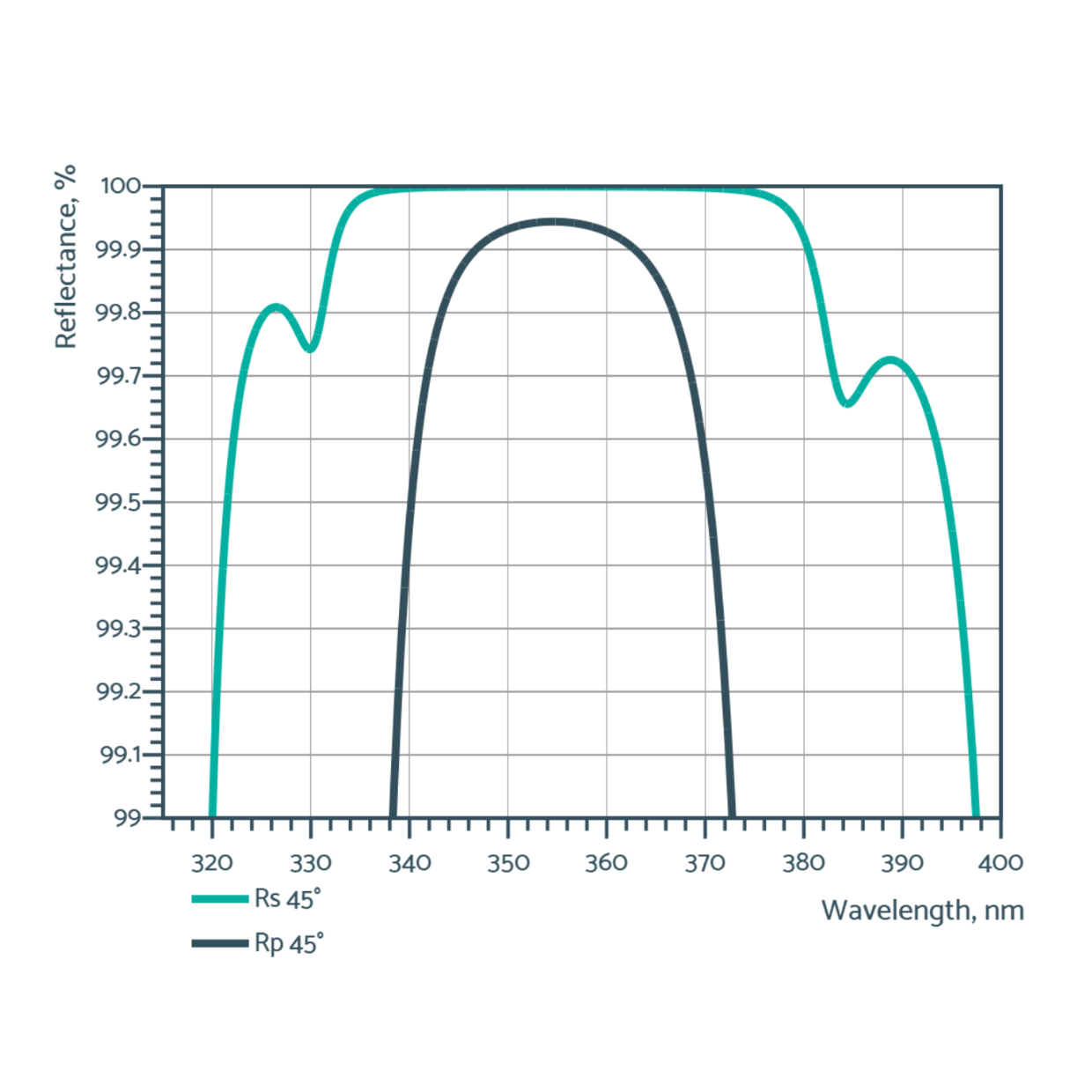

High LIDT mirror designed for Nd:YAG III harmonic.

- Higher longevity laser optics due to low absorption and low surface roughness

- High LIDT coatings featuring high reflectivity up to 99.9%

- Highly customised and application optimised solutions

Design example

Coating specifications:

Rs > 99.9% & HRp>99.8% @ 355nm, AOI=45°

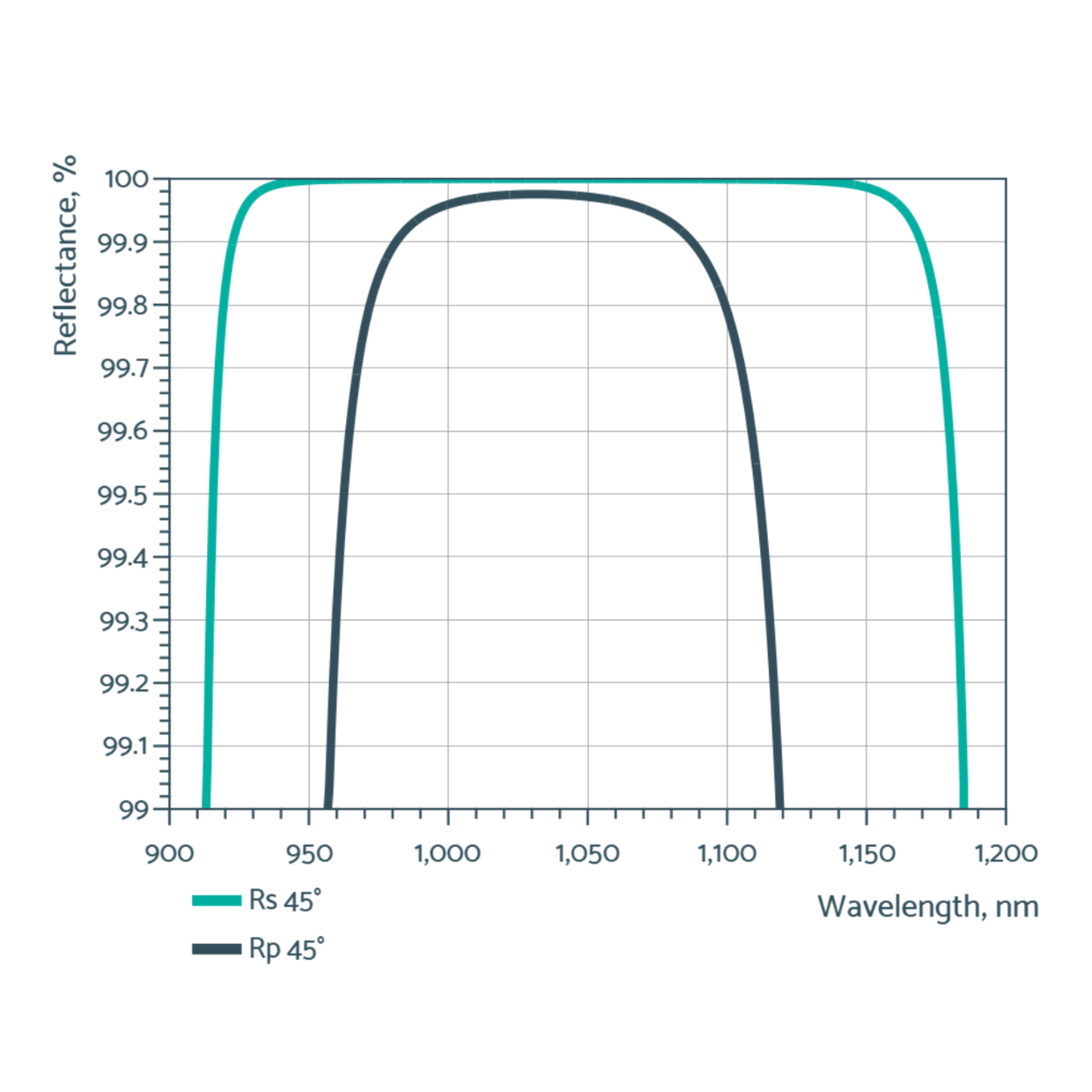

Superhero Power high LIDT mirror for Yb:YAG I harmonic.

- Long lifetime due to no color change mode of Laser-Induced Damage

- High LIDT coatings featuring high reflectivity up to 99.99%

- Highly customised and application optimised solutions

Design example

Coating specifications:

HRs>99.95% & HRp>99.9%@1010 – 1050 nm, AOI=45°

|GDD Rs|<10 fs², |GDD Rp|<20 fs²

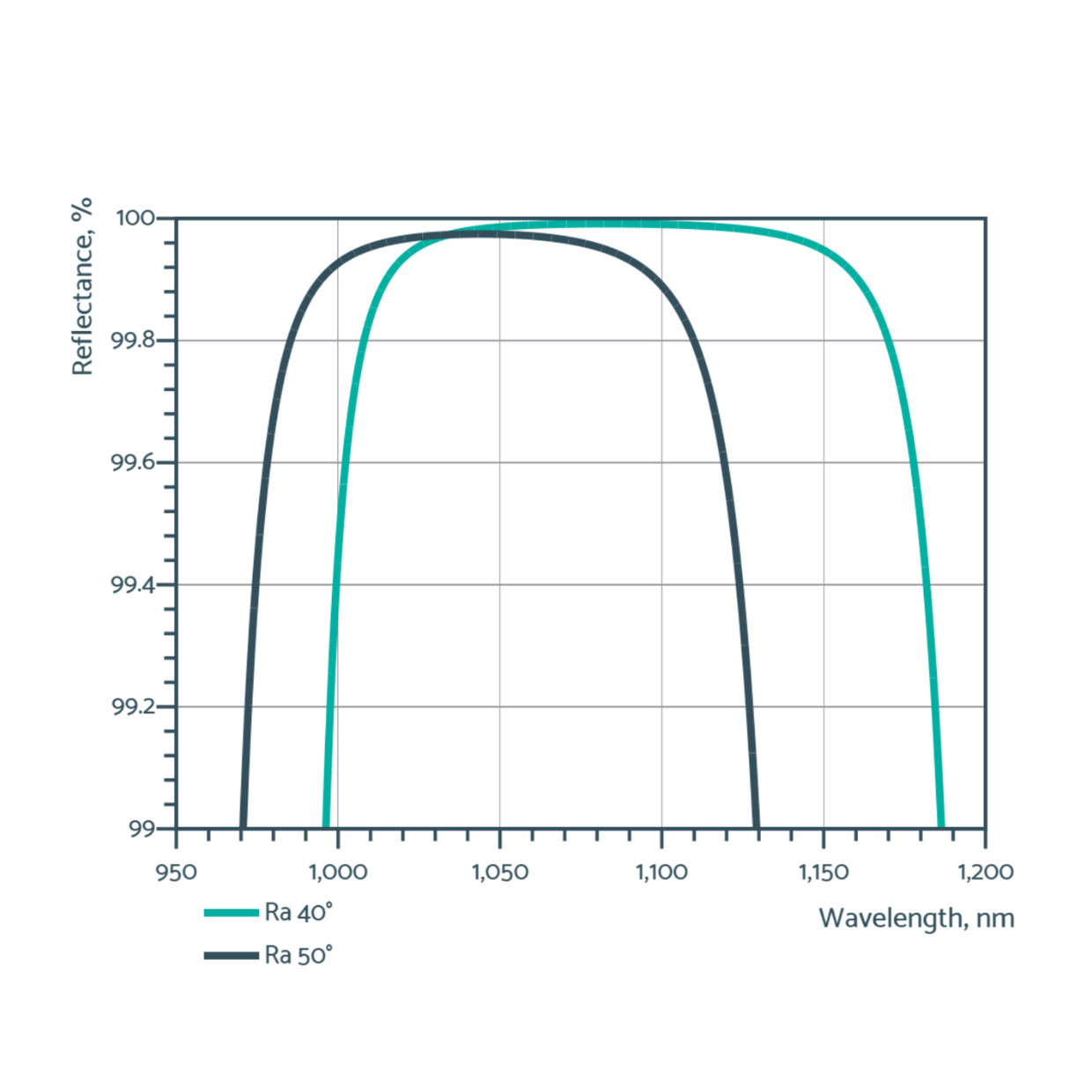

Low absorption wide-angle mirror for Nd:YAG I harmonic.

- Long lifetime laser optics

- Ultra-low-loss mirrors featuring low absorption

- High LIDT coatings featuring high reflectivity up to 99.99%

- Highly customised and application optimised solutions

Design example

Coating specifications:

HRa>99.9% @ 1064nm, AOI=40 – 50°

Certification

Here's what

our clients say

Laser engineers from fusion research companies appreciate OPTOMAN's transparency and reliability the most.

Many new scientific segment customers come to OPTOMAN because of peers' recommendations, as 9/10 customers would recommend OPTOMAN to colleagues.

Fill out a custom request

Relax and build your laser. OPTOMAN has your back.

Thank you

for your request

We will contact you as soon as possible

CONTACT OPTOMAN

Andrius Žvirgždys

Fusion Market Development Manager