High power laser mirrors for PW and TW lasers

The field of photonics is constantly evolving, driven by researchers who seek to understand, refine, and innovate. Some of these researchers across the globe push the boundaries of what is possible, relying on high power laser mirrors.

Among the most fascinating achievements in this field are the developments of Terawatt (TW) and Petawatt (PW) lasers, which demand high power laser mirrors capable of withstanding extreme intensities. These advanced optical components play a critical role in ensuring beam stability and precision across various applications, including advanced material processing, inertial confinement fusion, and ultra-high-intensity interactions.

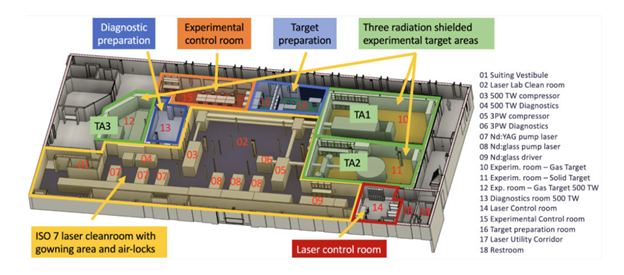

The scary TW and PW lasers deliver incredibly high peak powers and are capable of reaching laser pulses characterized by tens of femtoseconds, hundreds of joules, and high repetition rates, which can be used to investigate interesting phenomena, including ultrafast processes in physics, chemistry, and biology. These types of lasers are investigated in many facilities, including ELI-NP (Romania), J-Karen-P (Japan), SULF (China), LaserNet US facilities, such as CSU, LBNL, LLNL, OSU, and many more.

While the laser systems at these facilities are scary due to their extreme peak powers, they are also astonishingly big. For example, the user facility of the ZEUS laser (Zettawatt-Equivalent Ultrashort pulse laser System) system at the University of Michigan, which will be able to reach 3 PW peak powers, is enclosed in ~16,000 square feet of space.

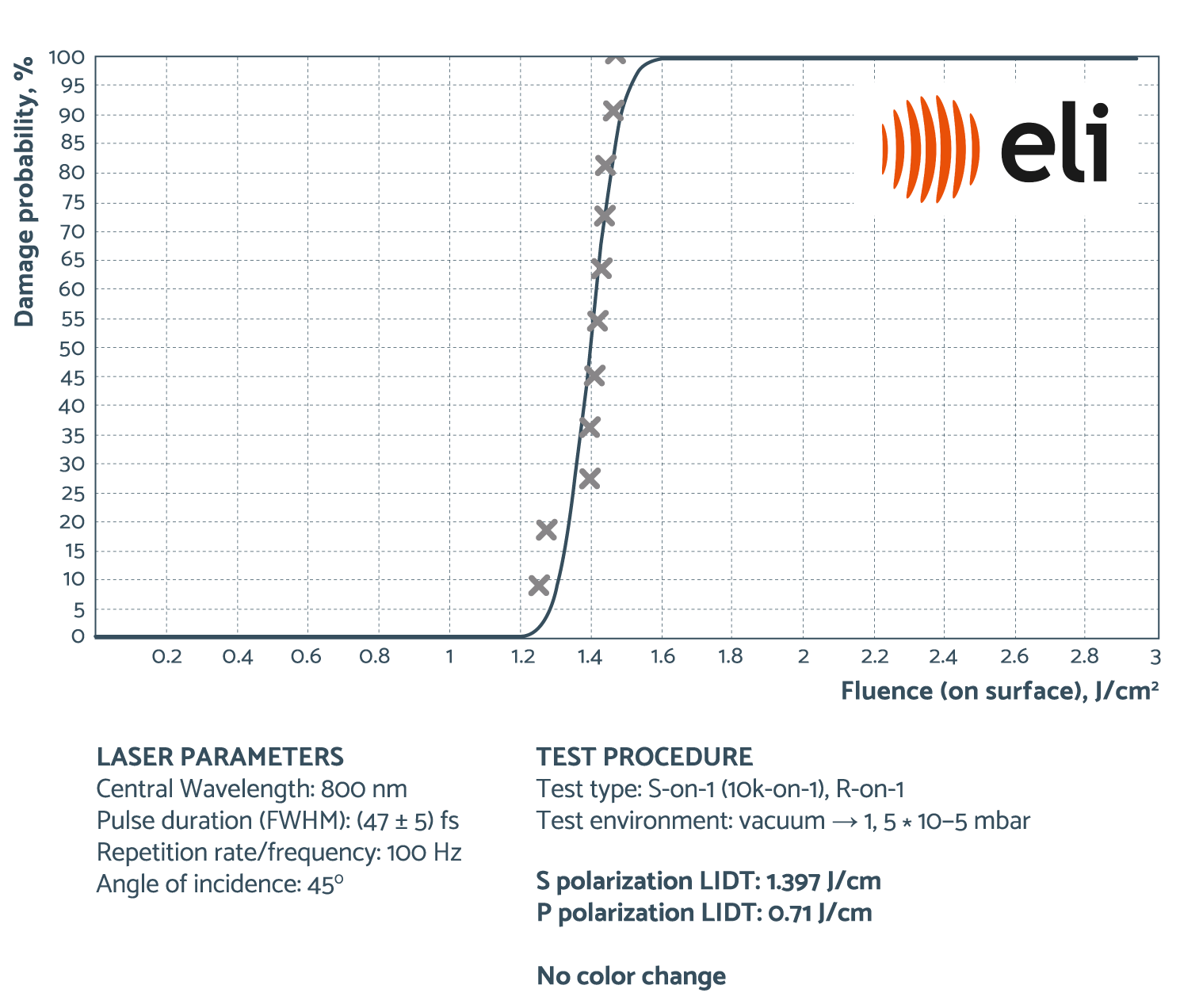

- Very high LIDT, reaching values such as 1.4 J/cm² @ 800 nm, 47 fs, 100 Hz, 97.6 µm.

- Excellent spectral performance (HR>99.99% @ 980-1080 nm)

- Low absorption (<1 ppm @ 1030 nm)

LIDT measurement at ELI beamlines

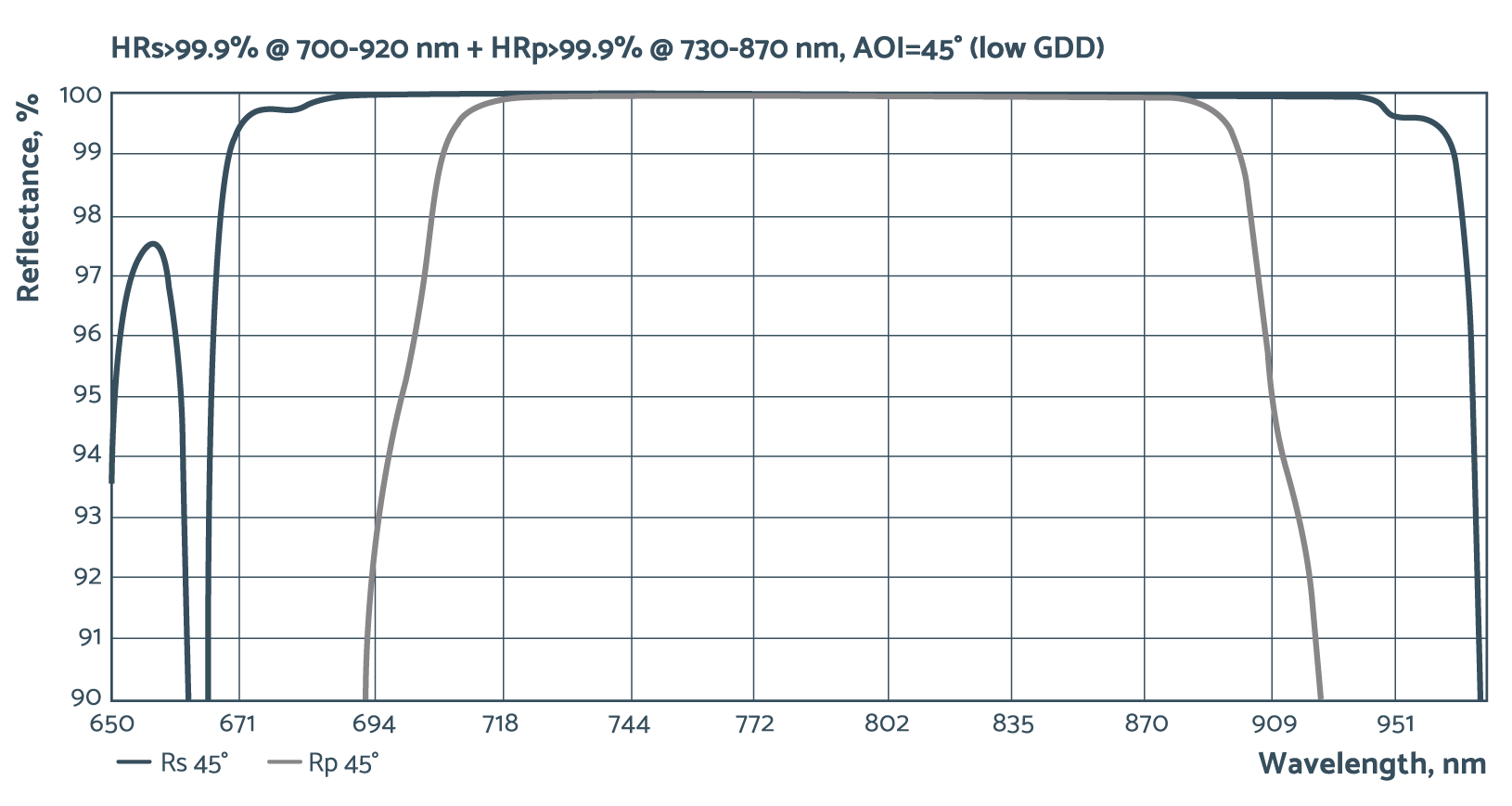

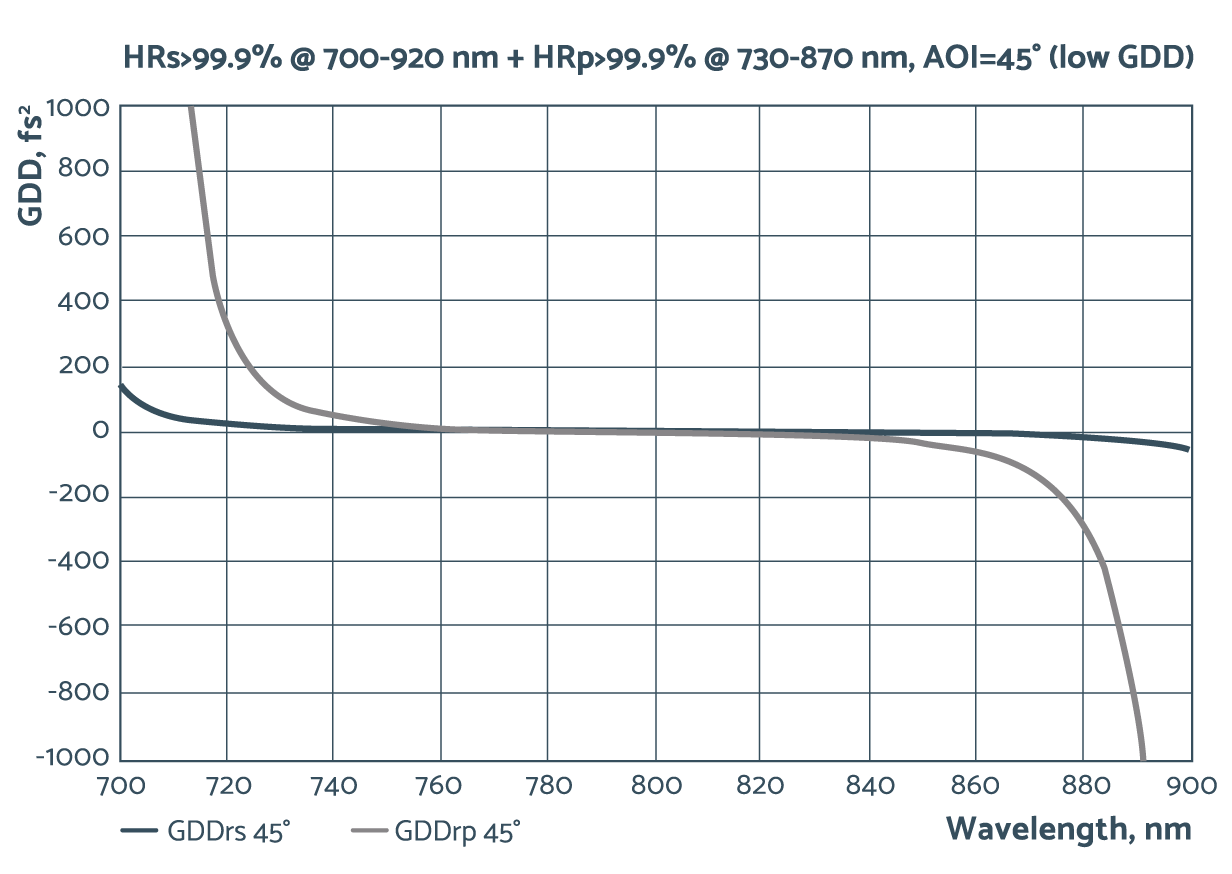

Design example of mirrors optimised for Ti:Sapphire lasers

Design example of mirrors optimised for Ti:Sapphire lasers

One of the most challenging coatings to design and manufacture is high power laser mirrors for Multipass Cells (MPCs). The main requirements for an MPC mirror are large reflection bandwidth, high reflectivity, high LIDT, and low group delay dispersion (GDD). OPTOMAN sees considerable potential for MPCs as their adoption in laser systems might help reach TW & PW peak powers. For this reason, OPTOMAN developed dielectric high power laser mirrors optimised specifically for MPC applications. OPTOMAN offers flat, concave, and convex broadband mirrors that possess all the features mentioned before high reflectivity (R>99.98%), high LIDT (>0.7 J/cm² @ 1030 nm, 180 fs), and low and spectrally uniform GDD. Read more about mirrors for Multipass Cells.

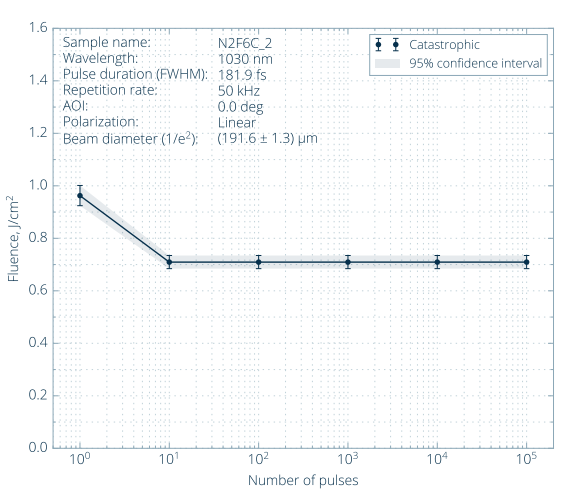

LIDT measurement done at Lidaris

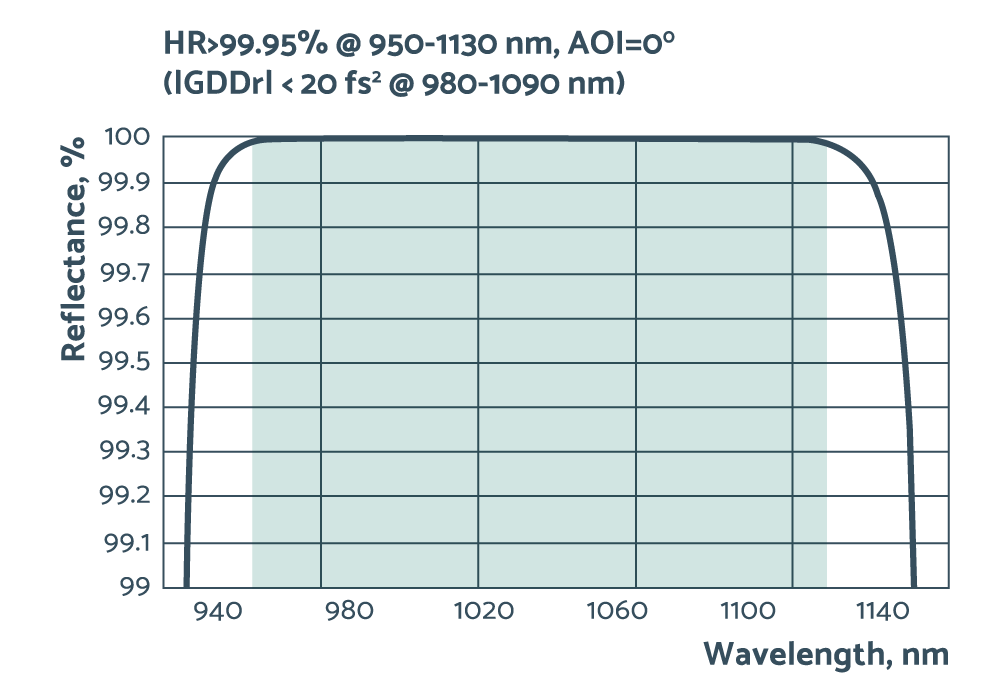

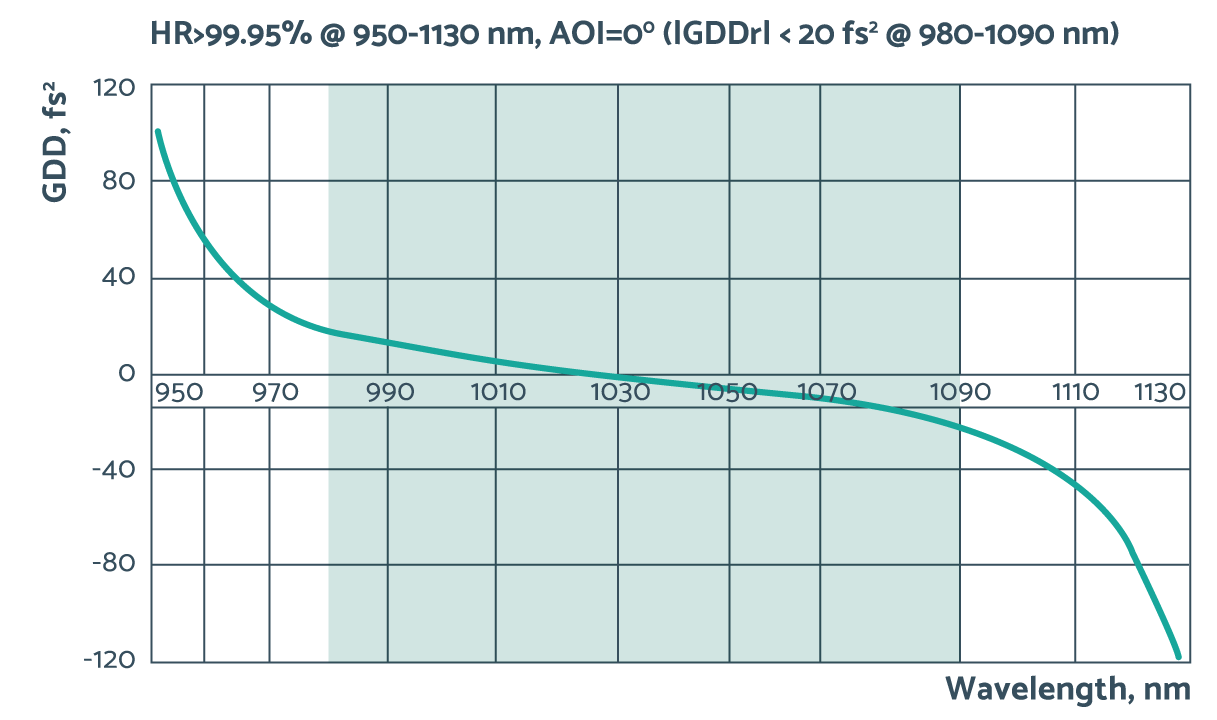

Design example of laser optics optimised for MPCs

Design example of laser optics optimised for MPCs

LIDT measurement of the OPTOMAN MPC mirror demonstrates that the mirrors don’t suffer from the degradation effect. The laser fluence level that causes damage remains constant, even with an increasing number of pulses. This is extremely important and beneficial for powerful ultrafast lasers, as the mirror has an enhanced lifetime. These high power laser mirrors ensure long-term reliability in demanding applications, making them a critical component in high-intensity laser systems.

Overall, the advancements in TW and PW lasers represent a big leap forward in photonics. The combination of ultra-short, high-energy pulses has opened the way for numerous scientific, medical, and industrial applications. As researchers continue to explore these technologies, the impact of TW and PW lasers on the ability to innovate will only grow stronger. None of it would be possible without application-optimised high power laser mirrors and laser optics—because your laser is only as strong as its weakest link.